(1)Using recycled materials(wood powder and plastic),green,low-carbon and economic.

(2)Waterproof and moisture-resistant.It can be used to the environment that traditional wood products cannot be applied.

(3)High strength, durability is better than the ordinary wooden materials.

(4)It has natural woodiness surface, the color can be customized according to your needs.

(5)High plasticity.It can be very simple to create and reflect personalized style.

(6)Pollution-free,product does not contain benzene substances

(7)Anti-UV,Inflaming retarding

(8)Simple installation,saving time and cost

(9)Low maintenance.

-

木塑共挤产品

木塑共挤产品

-

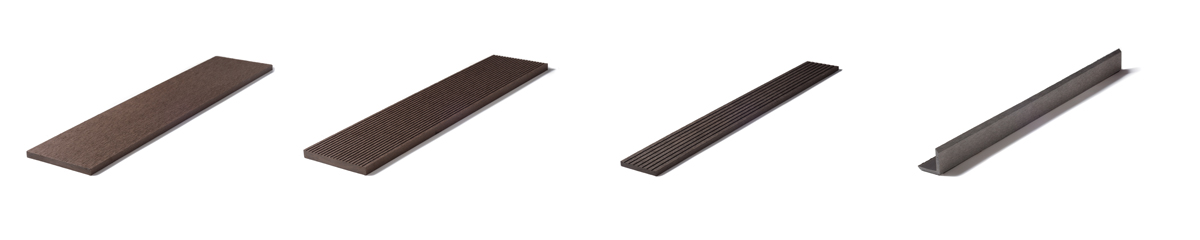

XF-0012

XF-0012

1.Wood Powder: 55% + Plastic (HDPE): 30% + Additives: 15%

2.It was extruded together by two different WPC materials in an especial process.

3.This not only retains the advantages of traditional WPC products, but also shows some more significant advantages.

Material:Wood Powder: 55% + Plastic (HDPE): 30% + Additives: 15%

Size:140*15mm/145*12mm/57*10mm/48*48mm/80*10mm etc

Material: stainless steel Size: OEM Surface treatment : polishing Production process: stamping

Use an electric-drill to drill holes on the external side of the first grooved decking, then screw in stainless nail to fix the decking to the keels. Plastic fitting have to be placed to the groove sides of the decking on line between every two decks. After finish arrangement of both the decking and the plastic fittings, two people at the opposite side of the boards, pushing the boards together to make the boards lean to each other firmly. Then screw in the stainless nails to all of the plastic fittings, which have a hole in the middle.

-

Maintenance

[Maintenance and care]

-

Attentions

[Maintenance and care]